We help you connect with the resources and services required to move your technology needs forward. On top of our advanced equipment capabilities, our resources include leading experts in the fields of engineering design, productivity enhancement and automation, instrumentation, reverse engineering, and student project support.

3D scanning and prototyping

- Digitizing of physical components and spaces through the use of state-of-the-art 3D scanners

- Creation of pre-production prototypes from conceptual designs

- Prototype validation

- Manufacturing process development

Using two different 3D scanning technologies, we can capture real-life objects as digital 3D models. With a surface point accuracy of 50 microns, every subtle detail is captured. 3D scanning has a broad range of applications that includes a having a reference to design around, restoring lost CAD files, manufacturing verification and quality control.

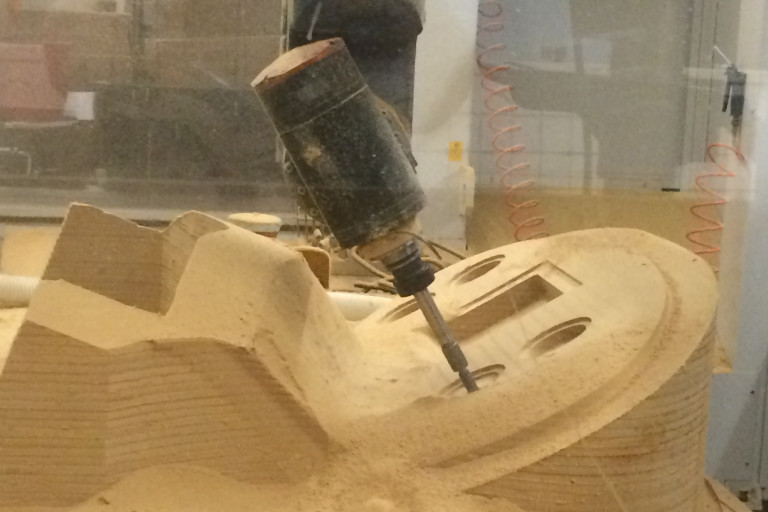

Camosun uses two rapid prototyping technologies, each the premiere technology from the world's largest 3D printer firms. The SLA machine simulates the material properties of many plastics, with a super fine layer resolution and surface finish. The FDM machine builds parts by depositing a bead of high-strength plastic at the finest resolution possible for the technology.

Productivity enhancement

- Current state assessments of existing production lines and processes

- Simulation of manufacturing work environments

- Proposal for improving throughput and productivity while minimizing waste

- Evaluation of technological tools to assist with improving productivity

Productivity enhancements start with an evaluation of your current activities, looking for simple means to improve work-flow and worker comfort. In many cases, automation will be identified as a tool to provide accuracy and reduce fatigue. In some cases, robotics will be the automation tool of choice to provide high impact for a fairly low cost.

We can model your industrial process, develop the tooling requirements, and help you implement solutions that will cut cost and increase production.

Common applications include: automating packaging operations, feeding raw materials, product sorting, and more. We'll also work with you to develop custom tailored automation to increase your productivity to unrecognizable levels.

Composite tools/parts manufacturing

- Design and manufacturing of composite tooling (fibreglass and carbon fibre reinforced plastics)

- Manufacturing of composite parts

Technology & human performance

- Design and manufacturing of custom equipment for people with physical disabilities

- Development of studies to assess human performance

- Adaptation of technological tools to improve human performance in the work environment

Training content development

- Development of digital training material

- Creation of immersive training environments through the use of Augmented Reality (AR) and Virtual Reality (VR) tools

Biochemical/chemical technologies

- Investigation of chemical components integration into existing products

- Observative reporting on chemical use and effects

- Research and development of recreational and non recreational Biochemical products

Abilities enhancement

- Working on innovative projects in the realm of para-athletes and para-athleticism

- Recreational activity prototyping and development

- Wearable technology design, development, and integration